Midtown community, businesses struggle with supply shortages

Amid nationwide supply chain struggles and inflation, local businesses and community members feel the effect of a disrupted economy.

January 28, 2022

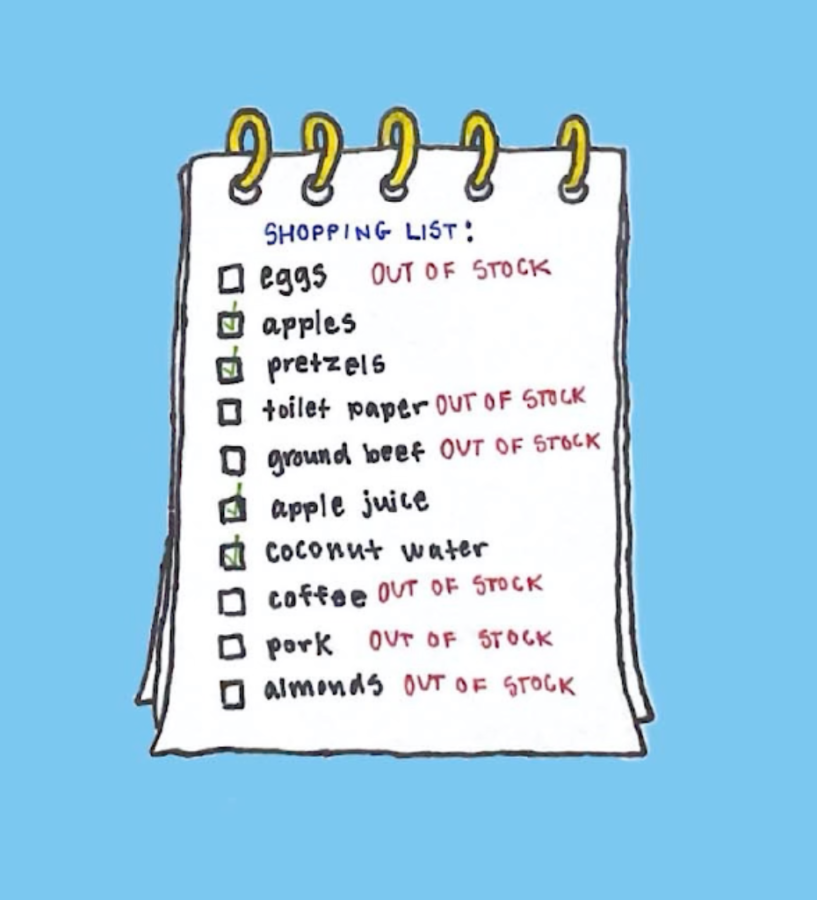

Due to supply shortages, shoppers find themselves playing a guessing game of what will be available when they go shopping.

According to the Bureau of Labor Statistics, pricing for the all items index has increased 7% in the past 12 months. This is largely because of supply chain issues, which have also caused delays. . This jeopardizes shopping for consumers in the US.

Trader Joe’s store manager Areon Bates said behind the scenes, delays are causing complications with business.

“What we’re running into now is mainly import delays,” Bates said. “Some things aren’t able to pass customs, or to get into the states for us to actually get it in time or somewhere close to when they say we might get it. A lot of times we are expecting things to come, they still aren’t available for us.”.

Bates said shortages have been normal throughout Covid, and the workers at Trader Joe’s have to “take it in stride.”

“We just roll with it and recommend other things for our customers,” Bates said. “Trader Joe’s loves the other companies and competitors, so if there’s an item I know we don’t personally carry, we’re more than happy to recommend another place that has it.”

Bates said there isn’t a specific theme of items that aren’t available, or in short supply.

“Jackfruit was an issue, and coconut-based items were an issue a while ago,” Bates said. “Right now there’s a glass shortage, so items that have glass containers sometimes become an issue. There was a meat shortage, but it’s kind of leveling out right now. It’s mostly random things that aren’t available at the moment.”

Despite supply shortages at Trader Joe’s, prices have not been affected.

“We want to make sure that we give everybody the best price possible, so if it becomes an issue of the prices are raising to get it, we will just discontinue the item altogether,” Bates said.

Amid non-transitory inflation and rising prices nationwide, some businesses like Virginia Highlands’s Doc Chey’s have dealt with supply chain issues differently.

“We had a menu-wide price increase in mid-2021 by 50 cents an entree, which helped us cover the rising cost of food and also the rising cost of labor, which was huge,” Doc Chey’s partner and operations manager Melanie Vaughn said.

Vaughn said another reason Doc Chey’s had to increase the prices of entrees was that workers’ wages had increased substantially in the restaurant.

“I think that this industry lost a ton of people…For instance, you could walk into Target with no experience making 15 bucks an hour on your first day,” Vaughn said. “There was that factor of raising wages outside of us.”

Doc Chey’s serves pan-Asian food, so the restaurant was greatly affected during the height of pandemic-related struggles in some Asian countries.

“We use a lot of Asian products from Thailand, from China and Vietnam to make a number of the items we make here,” Vaughn said. “all those countries experienced an incredible rate of Covid and were trying to shut down and tried to control the shipping and stuff, so that cut it down as well.”

Doc Chey’s has been operating under the threat of having to shut down their restaurant due to worsening supply chain issues.

“We just tried to figure a way around it,” Vaughn said. “When we couldn’t get the Brussel sprouts or when we couldn’t get the green beans, [we took] them off the menu for the evening or for the week or for the month until we could get them again.”

Midtown cluster parent Alex Pivoshenko explains that he has had issues with his family’s kitchen renovation and getting the materials for it.

“We’ve been in the planning stages for over a year and a half now. It took many many months to get the appliances, so everything was back ordered,” Pivoshenko said. “We planned to get certain appliances. The wait was six months, so we decided to get different ones, but in the end, we couldn’t get the contract in six months anyway.”

Stainback Hess Studio architect James Hess said the supply chain issues have caused delays for many materials. Because of this, clients often have to make difficult compromises in their building projects.

“More often than not, our clients have not built before and don’t know the process, so it leads to them making difficult decisions like reducing their wishlist (appliances) or reducing the house size,” Hess said.

Many construction materials have gone up in pricing substantially.

“Framing has gone up 20 to 30% in things, window pricing has skyrocketed, across the board, everything has just gotten more expensive,” Hess said.

Hess believes the supply chain issues may not resolve well for the building industry.

“These problems will continue, so I think that the way it’s going to end is that people won’t be able to afford their house anymore, so they’ll just put the products on the back burner for a period of time,” Hess said.

Bates thinks that consumers and businesses may have to be patient and try to adjust to this new norm.

“It’s just a matter of people becoming more comfortable in the world that we are living in with covid,” Bates said. “I don’t think that there’s really anything that we can do until things just move along.”